E'kabel Blog

UL Cables:

The marking that defines safety and excellence in every connection

In the world of electrical equipment, the configurations are virtually limitless, and cables are no exception. Factors such as size, insulation material, voltage rating, and various testing standards contribute to the complexity, making it challenging to identify a cable’s general and construction characteristics at a glance.

While certain elements—like jacket color, conductor size, or armor type—can provide clues about the cable being installed or analyzed, they often fall short in revealing the specific tests it has undergone or the construction standards it meets. This underscores the necessity for clear identification of cable attributes.

How to establish the identification and marking structure

Various standards and construction norms exist for different types of electrical cables, such as ICEA, IEC, NMX, and UL, each specifying its own identification and marking structures. While these standards share many common elements, this article focuses on the marking of electrical cables under UL standards, given their growing relevance and importance in recent years.

UL (Underwriters Laboratories) is an internationally recognized certification and safety organization that sets standards for the safety of electrical products. UL cable marking is a certification and labeling process used to demonstrate that cables meet the safety and performance standards established by UL. As an independent testing and certification entity, UL evaluates products to ensure their compliance with applicable safety norms.

Marking structure

Electrical cables are subject to various UL standards, each defining the minimum requirements for their identification and marking. However, before a cable can be marked under UL’s structure and certification, it is essential to fulfill three key elements:

- Product evaluation: UL conducts comprehensive tests on cables to assess their performance and safety. These evaluations may include fire resistance, ultraviolet exposure, electrical properties, and mechanical strength, among other criteria.

- Factory inspection: UL performs regular inspections at manufacturing facilities to ensure adherence to established quality and safety standards. This process encompasses the review of production processes, quality controls, and the traceability of materials used.

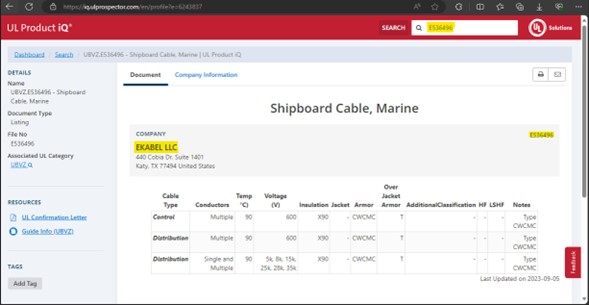

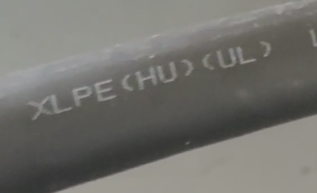

- Certification and labeling: Once cables have passed evaluations and comply with UL standards, they receive the corresponding certification. Certified cables may display the UL logo or the “(UL)” identification and are assigned a UL file number known as an E-file, consisting of an “E” followed by six digits (e.g., E509288). This marking indicates that the product has been evaluated and meets the safety and performance requirements established by UL.

Once these three steps are completed, a UL-certified cable manufacturer can mark the various characteristics and tests that a cable has passed, providing customers with the assurance that the product they are purchasing meets UL’s specified standards.

However, a question arises: How can I, as a customer, verify that the cable for a projct is truly certified?

There are three simple ways to verify that a cable is genuinely certified and endorsed by UL:

- By consulting the Efile number marked on the cable at htt

ps://iq.ulprospector.com/

3. Consulting the UL marking guide and approved codes that establish the mandatory elements to be marked on a certified cable. Wire and Cable Marking and Application Guide | UL Solutions Code Authorities

These three elements, primarily, together with those established by each UL standard, guarantee that a cable is UL certified. Let’s take the following example to analyze:

EKABEL IP1808 E509288 8PR 18AWG CU PVC 300V 105C ISOS (UL) TYPE PLTC PVC JKT FT4 SUN RES FLAME RETARDANT WET LOCATIONS ROSH COMPLIANT (X1) 2023 2400m

As observed, the sample marking complies with UL requirements, primarily displaying the Efile number and the UL certification mark. The cable, having passed flame retardancy, sun resistance, and wet location tests, is marked as FLAME RETARDANT, SUN RES, and WET LOCATIONS, ensuring, through certification, that the cable meets the requirements of these tests.

The Importance of authenticity in UL certified cables

A cable certified by UL is synonymous with quality and safety. UL provides the tools to ensure that the certifications and tests marked on the cables comply with high quality standards. It is always necessary to verify that the Efiles printed on the cable jackets are current and that the listing mark (UL) is visibly there. These elements guarantee the validity of the certifications together with the documents that UL provides to manufacturers, such as Compliance letters. Falsifying information is grounds for a procedure by UL that can result in the removal of certifications and, consequently, the quality and trust of the product would be affected. Ekabel has 11 UL listings that guarantee the quality of our cables, including:

Author:

Engr. Jesús Vargas

Electrical & Communications Systems (ECS) Solutions Specialist