E'kabel Blog

Technology and Evolution

Fire resistant cables

Accidents in industrial settings seem unlikely to happen until they do. In particular, fires are the most dangerous and may spread fast if there are elements that favour the spreading. Learn how cable technology can contribute to reducing risks.

In the Oil & Gas Industry, there are favourable conditions for a fire to escalate quickly and uncontrollably. Flammable compounds are the norm in that environment, and therefore safety precautions must be strictly followed.

In this context, it has been understood for years now that a cable is not a passive element in a fire risk environment. If a cable has poor specifications or special conditions are not considered during its manufacture, this can directly impact fire control, and consequently increase the magnitude of the accident.

Additionally, cables are among the elements that must resist fire and continue operating since the activation of fire alarms, ventilation systems, sprinkler systems, among other basic functions depend on their operation. In short, if a cable fails, the chances of a fire resulting in loss of life and property are greatly increased.

Ceramifiable Technology

Ceramics has existed for millions of years; it emerged as an artform in China and Japan at the end of the Palaeolithic period. This material, by definition, is fireproof and prevents the propagation of fire. It does not burn or melt even when it comes into direct contact with fire, nor does it emit toxic fumes. This is how people first thought to use this millenary material to protect electrical circuits in case of fire. But the question remained: how can ceramics be incorporated into cables when the two elements seem to be incompatible?

The answer came when research made it possible to incorporate a special chemical compound into cable insulation that transforms into ceramic when its temperature is increased. This is Ceramifiable Silicone technology.

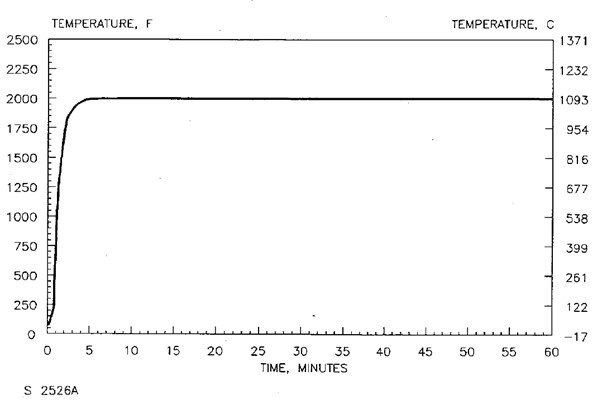

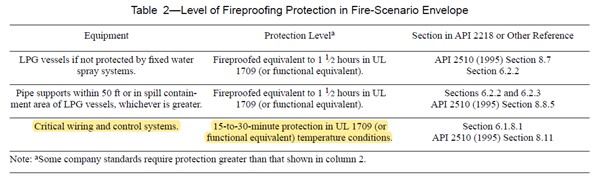

Cables with ceramic silicone technology can withstand 60 minutes at 2000°F, using the UL-1709 time/temperature curve recommended by API 2218, without compromising performance. Additionally, there are special cable constructions with this insulation technology that can withstand up to 180 minutes at maximum temperatures of 2000°F (1096°C) demonstrated in IEC 60331 tests.

To achieve this, the cable’s construction has also evolved to aid safety. This cable requires additional internal layers such as thermal barriers, and its core is made of nickel-plated copper to withstand temperatures higher than if it were only copper.

Safety also has financial advantages

This type of cable construction has become the safety standard required by the oil industry, and the American Petroleum Institute (API) has established it in the best construction and safety practices for high fire hazard facilities (API 2218 – Fireproofing Practices in Petroleum and Petrochemical Processing Plant).

“Ceramifiable cables are now the safety standard in the oil industry”

Ceramifiable cables are not only a smart choice in terms of operational safety but also in financial terms. In terms of insurance premiums for oil companies, the use of these cables is a factor that reduces the amount to be paid. This is basically because it guarantees correct performance in risky situations, and it is an element that insurance companies also value.

There are cases where oil operating companies have obtained reimbursements and repair costs for damages from insurance companies, thanks to having these special cables installed in high-risk fire hazard environments.

Author:

Andrés Flores, Engineer with over 20-year experience in Energy Systems, MBA, Country Manager and E’kable CCO.