E'kabel Blog

The cost of a 1/3 CN conductor can be between 38% and 63% of the Full CN

What is the Cost of Getting Cable Sizing Wrong? A Practical Case

With the increase in the price of metals, the sizing of a cable has become key. Get to know the economic implications of changing from 1/3 Concentric Neutral to Full Concentric Neutral through the use of an additional copper conductor. You will find in this study the calculations for an average project of 100,000 ft. in which the appropriate cable shield selection can mean a saving of up to 25%.

In the electricity industry, the distribution and transmission area has given cause for endless studies relating to the different configurations permitting more efficient handling of capital investments (CAPEX).

One of the most studied cases has been that of medium voltage distribution cables, especially in recent decades, due to the volatility of raw materials prices and also the increase in production and logistics costs. All this has driven the quest for efficiency in the economic aspect.

Historically, oversizing both conductor and copper shield had come a widely extended practice with economic repercussions which were assessed as “low”.

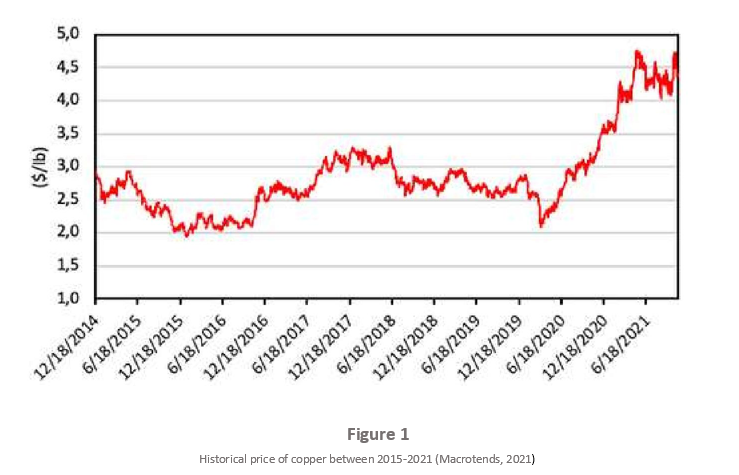

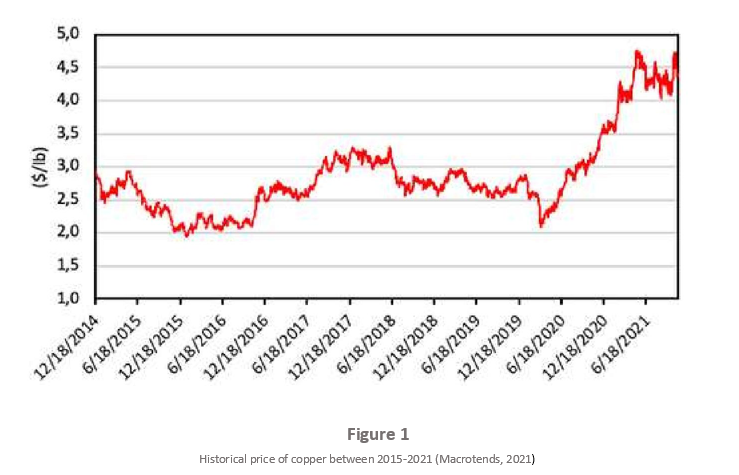

However, with the variation in copper prices (Figure 1.) which is displaying an increase of more than 120% between 2020 and 2021, arises a genuine doubt about the sustainability of this practice.

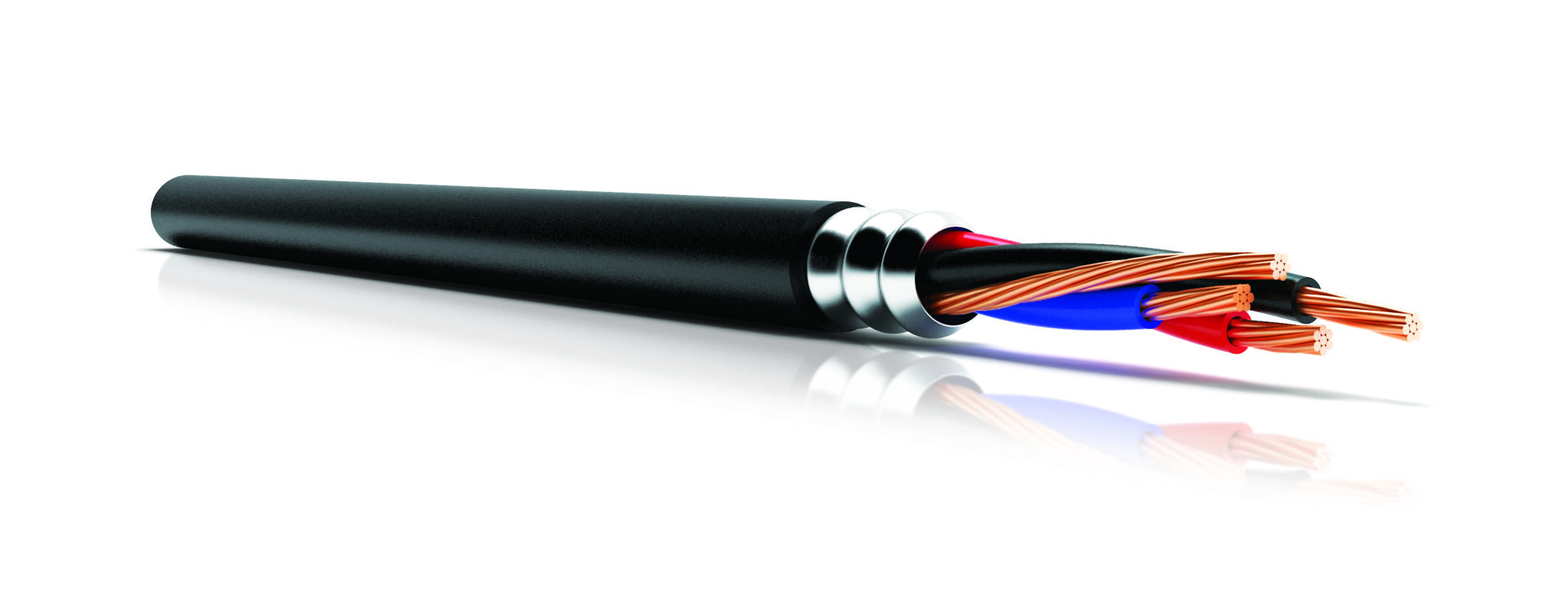

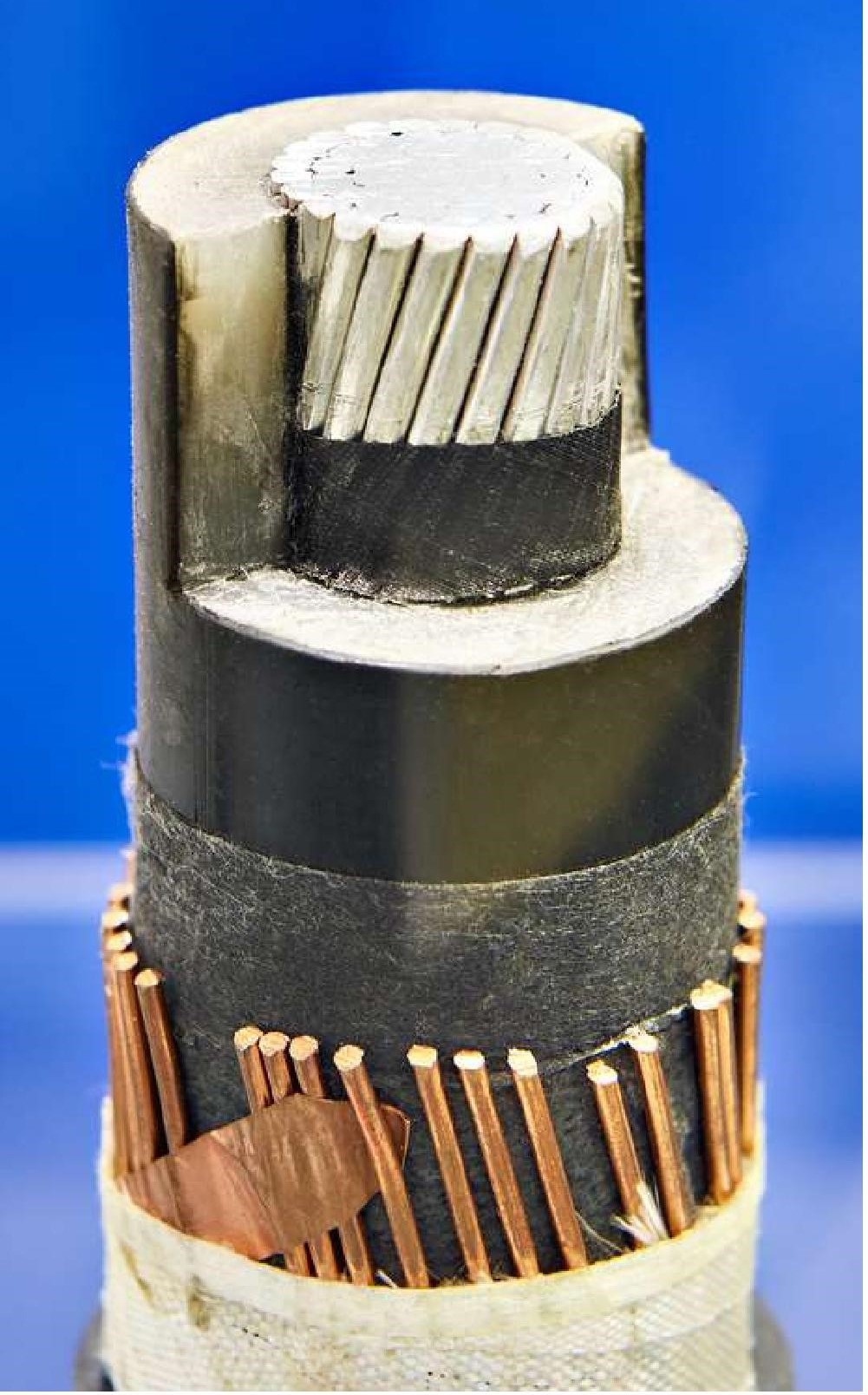

Use of cables with Concentric Neutral (CN) has represented an improvement on electrical installations by maintaining both system’s neutral and earth in the same cable. The neutral, when installed on the active conductor, radially involves a minimum increase in the cable diameter allowing more efficient and less repetitive installation since the fitting of parallel conductors is not required.

Set out below is an evaluation of the implications on the sizing and selection of the Concentric Neutral gauge. Generally, this analysis involves purely technical variables in which the unitary economic change is practically negligible.

However, this technical-economic analysis contrasts different angles by using metric calculations for an average project of 100,000 ft. For this, a copper value of $/lb 4.372 plus a transformation premium of $/lb 0.400 is used.

The sizing of the neutral conductor in distribution cables brings with it significant technical implications; a variable current will flow through it and its ampacity will be influenced by external factors; due to the Joule effect, it will generate heating into the cable jacket (its own insulation) and also a synergic effect on performance for both itself and active phases.

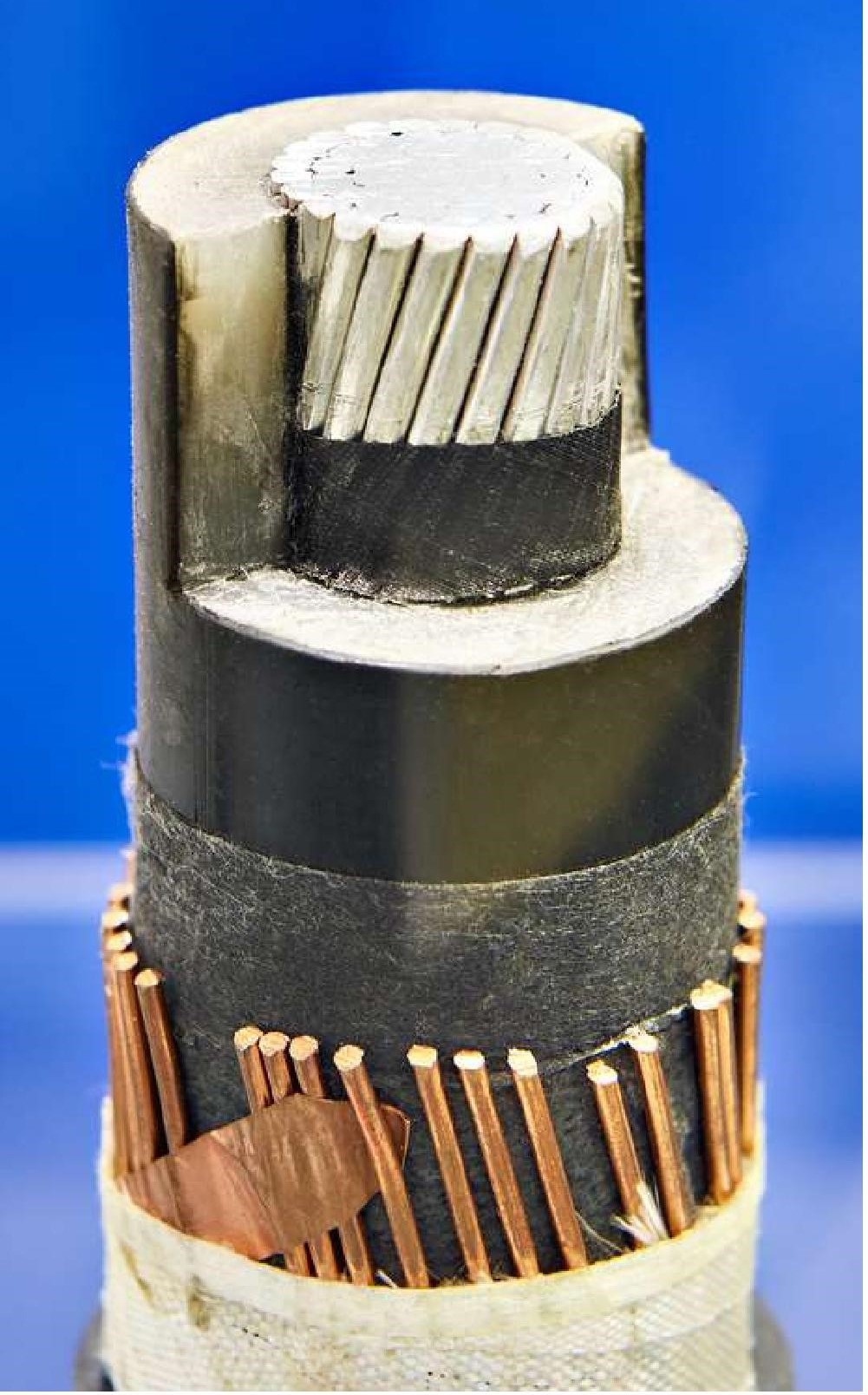

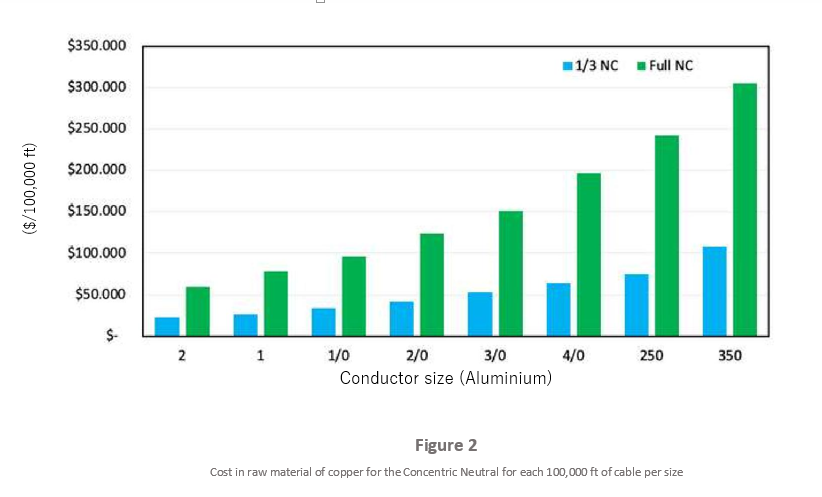

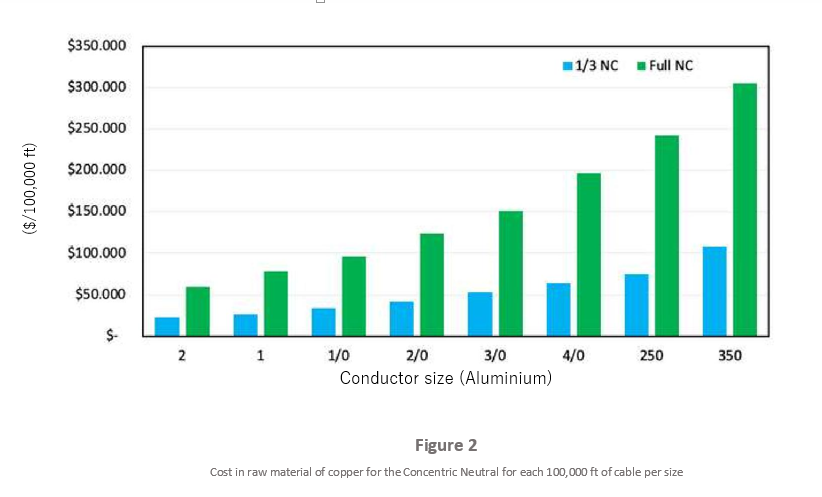

In addition to this, the costs differences between using a 1/3 Concentric Neutral (1/3 CN) and a Full Concentric Neutral (Full CN) (both defined and standardised in ICEA standard S-94-649) are considerable (Figure 2).

The cost of a 1/3 CN conductor can be between 38% and 63% of the Full CN. This implies savings of up to $200,000/100,000 ft for 350KCMIL aluminium cables.

Therefore, with a view to optimising costs, the 1/3 CN solution is usually employed at distribution level. Deficient sizing, in which 1/3 CN has a lower ampacity than required, would involve its overheating.

This might compromise the integrity of the insulation (the cable’s outer jacket); causing incipient faults and increasing the possibility of permeability of liquids and gases which might generate corrosion in the wires of the concentric neutral and even failure of the conductor.

“The cost of a 1/3 CN conductor can be between 38% and 63% of the Full CN.”

Considering this, sometimes it may be necessary to change the 1/3 CN configuration to Full even after the cable has been installed.

Logically, changing the whole of the feeder to include the transverse section of the additional CN does not represent a technically or economically feasible solution. Therefore, the installation of an additional conductor is carried out, which operates as an extra neutral conductor to take the missing 2/3 to Full Concentric Neutral configuration according to its transverse area.

To guarantee the ampacity corresponding to a Full Concentric Neutral conductor, the size of the additional conductor must have at least the transverse area missing between the current installation and the desired one.

Table 1 presents the transverse sections in KCMIL for both configurations, their difference and the equivalent size to be installed to change from 1/3 CN to Full CN. This shows that the change involves the installation of a 6AWG copper cable.

In order to optimize investment, it would seem logical to install the nearest direct size. However, this correction is carried out after the cable has been purchased. Therefore, there are additional supply chain costs for the procurement of this single cable, and maybe other hidden challenges, such as low product availability that may impact overall project deadlines. Other possible costs are: delays, catastrophic failure or system integrity compromise.

Consequently, the additional size to be installed is usually the next commercial size larger than the technically correct one.

In addition, prior to the problems described above, the mere difference in raw material between both cases is assessed: Full CN and 1/3 CN + additional conductor.

In Figure 3, the difference can be observed in the total amount of copper between the constructions of Full Concentric Neutral and 1/3 CN + additional Conductor for a standard 100,000 ft project. It is to be expected that the greater the project value, the greater the gross difference will tend to be. Initially, for a 2AWG cable size, the difference is practically imperceptible, $1200/100,000 ft.

However, by increasing the size, this difference can go from $9,300 to more than $113,000 always in favour of the Full CN installation over 1/3 CN + additional conductor.

This revealing analysis shows the importance of correct specification during the engineering stage. Despite initially appearing more expensive, the implementation of a correctly evaluated Full Concentric Neutral can represent between $9,300 and $113,000 savings for a medium-sized project of 100,000 ft of medium voltage conductor.

This benefit does not even take into consideration supply chain costs, installation hours, additional accessories required and operational factors like corrosion, possible induced voltages and currents involved by the installation of an additional cable.